May 2003

Page 10

Page 1 | Page 2 | Page 3 | Page 4 | Page 5 | Page 6 | Page 7 | Page 8

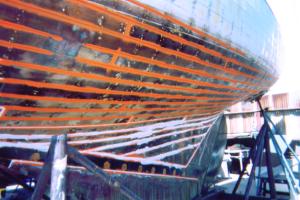

Boatwright David Cassie wields hammer and iron to "cork" the cotton

into BANANA'S seams.

Red lead is painted into the seams before the cotten is introduced.

(please see the article on CHELSEA for a better description of

"corking"). Here, the cotton is corked into seams on both sides of the

boat in a staggered fashion. Forefoot awaits corking..

Sikaflex is used to caulk the seams after corking with cotton and

painting over the freshly corked cotton with red lead.

This picture shows the teamwork between David Cassie and Keith

Smith. Keith prepped the seams, painted the first stroke of red lead.

David then corked the cotton into the seams. Keith followed closely

behind with the next stroke of red lead and the caulking with Sikaflex.

We chose white Sikaflex so as to better be able to read the condition

of the bottom paint as is wears off. Seams showing under bottom paint

will be a telltale of a long over due bottom paint job.

With seams yet to be corked above you can see hear the effects of a

team of boatwrights at work corking and caulking the bottom of BANANAS.

Excess Sikaflex has been cleaned off from finished seams above the

deadwood while David is corking the opposite side. When David shifts

over to this side of the boat to continue the corking, Keith switches to

the seams just corked on the opposite side by David and follows on with

the red lead and Sikaflex. Entire corking and caulking job (exclusive

of seam preparation) with the two of them working in tandem required a

total of about 40 hours apiece. They didn't wear themselves ragged, the

corking and caulking work is pure quality, and the expectation of a

swelling of the planks without drama exists.